NORITAKE PAST, PRESENT & THE FUTURE

Behind the secret of perfection in a product unfolds the legacy of an exceptional history. The establishment of a factory in Nippon Toke, Nagoya, Japan in 1904 was the birth of a giant in the global ceramic industry. Founded by Baron Ichizaemon Morimura and his colleagues, it is known today as Noritake.

Towards the end of the nineteenth century, the Americans too wanted the luxury of the type of art enjoyed by the European elite. New York was the central location of this renaissance. The European style art objects that an American family could display on their mantelpiece were products of early Noritake. For more than a century since through its innovative imagination and experience, Noritake has been able to hallmark the highest standards in porcelainware around the world

With they country’s rich artistic and cultural heritage, Sri Lankan pottery and craft dates back to the 5th century before the Common Era. This expertise is born of a composite tradition of centuries.The perfect blend of a technological giant in the ceramic production world with superior manpower distilled from a strong artistic tradition and craftsmanship brought about the birth of a hybrid to the industry of porcelain ware.

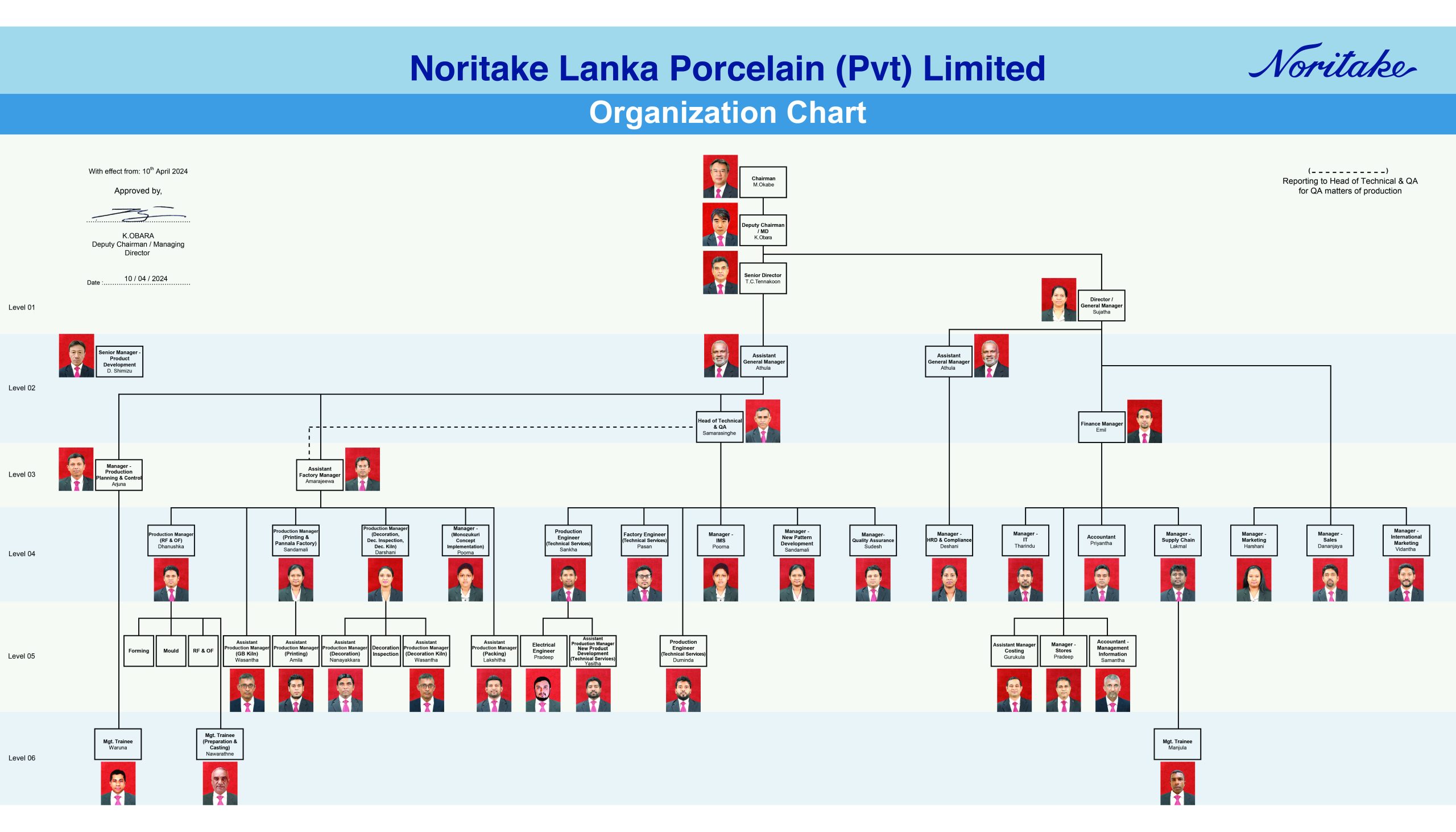

With the Noritake Company Ltd in Japan as the parent company, Lanka porcelain Pvt Ltd commenced their operations in Sri Lanka in 1972. Representing the Noritake global family in Sri Lanka the company has evolved into Noritake Lanka Porcelain, a new giant in the porcelain industry, earning a reputation in aninternational market fors tandard and quality.

The transformation of a handful of dust into a symbol of beauty reveals a spectacular story. Raw materials like Quartz, Feldspar andKaolin are crushed in a ball millfor 36 hours and the resultant liquid is dewatered and kept as a cake for maturing under ideal humidity and temperature.

The resultant liquid is dewatered and kept as a cake for maturing under ideal humidity and temperature. The seasoned cake is then driven through a mill to create clay cylinders used to sculpt the product. The Noritake factory is equipped with machines for both automatic and manual formation whether it is done manually or automatically.

Forming a porcelain object is an Art and Art cannot be without human intervention. Producing a cup is not complete until the edge trimming and handle attachments are done. The handle needs to be firmly pasted and accurately positioned.

The same applies to the construction of openings and attaching spouts and handles on a teapot. Only small and versatile feminine hands and patience with a suitable temperament can perform these exacting tasks with high precision. Sponging and finishing too require a gentle feminine touch.

Every stage of production is closely supervised by Japanese experts. Before going to the next stage of the process – the soft biscuit firing, the finished greenware is subjected to close inspection. The journey through this kiln moulds the greenware into ideal water absorbing conditions for glazing. The greenware is heated at 950 degrees Celsius, until it is fit to go to the glaze bar. The fired soft biscuit is inspected again for any damage before being sent for brushing and glazing. Skilled hands are required again at this stage of the process. Firmly holding a plate by the fingertips while dipping it into the recommended depth in liquid glaze is not a task for all. The machine is only to transport the glazed item while the glazing is done manually.

After sponging the edge or the foot, the glazed item is driven through a kiln for another round of heating called glossed firing. It is during this journey through the flames at a temperature of 1300 degrees Celsius that the item receives its shine. The heated item is exposed to another test which is known as the pipeware inspection. This inspection rules out any possibility of passing a blemished item beyond this point.

Then comes the most colourful part of the process, the decal application. Noritake Lanka porcelain uses both decalcomania and traditional hand painting techniques. The decalcomania technique is well suited for mass production. Patterns that are printed on paper are transferred to the piece, pasting the dampened paper with a pattern on the surface. Patience and concentration are essential human qualities needed at this stage to maintain the accuracy of the placement of the pattern. Then it is exposed to a third round of firing known as decal firing. The paper is burnt and the pattern with overglazed colours is transferred to the surface of the piece.

Hand painting by skilful artists gives a touch of uniqueness to each product. The gold lining is another task that requires skill. Delicate fingertips are well trained to move the pointer brush along a perfect path.This brownish coat converts to gold once burnt. The end product is finally inspected at this stage before being sent for packaging. No room is left in the production process for slipping in an inferior item to the market.

Noritake Lanka is confident and competent enough to guarantee the same quality that Noritake Japan has been maintaining through hundreds of years. It is a blend of superior technology and dedicated craftsmanship enriched by an enduring history.

JASTECA CSR/SUSTAINABILITY GOLD AWARD – 2018

NOTIONAL PRODUCTIVITY AWARD – 2014/2015/2016

CNCI ACHIEVER AWARDS – 2016 ACHIEVER OF INDUSTRIAL EXCELLENCE

CNCI ACHIEVER AWARDS – 2016 ACHIEVER OF INDUSTRIAL EXCELLENCE

NATIONAL BUSINESS EXCELLENCE AWARD

2015/2016

EDB PRESIDENTIAL AWARD – 2012/2013/2014/2015

NCE EXPORT AWARD.

2014/2015/2016

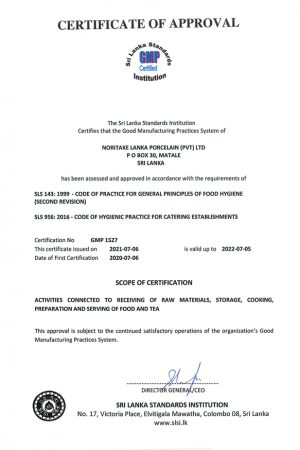

Good Manufacturing Practices (GMP) Certification

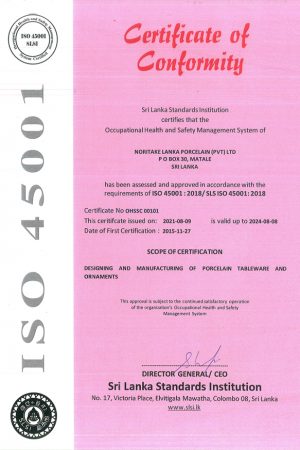

ISO 45001:2018 Occupational Health

and Safety Management Systems

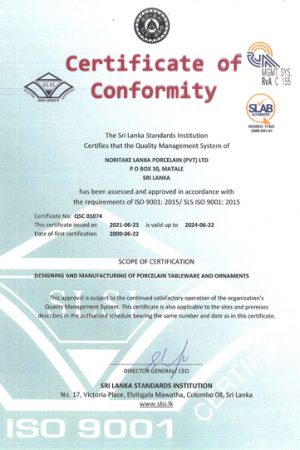

ISO 9001:2015 Quality Management

Systems

ISO 14001:2015 Environmental Management

Systems

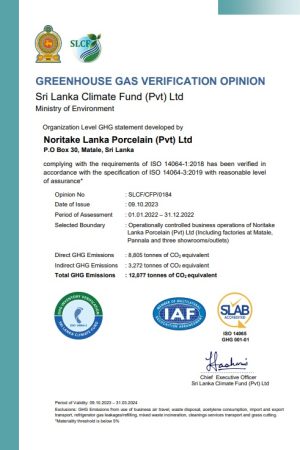

ISO 14064:3 2019 Greenhouse Gas

The Noritake Hand Painting Outlet in Pannala is where you can witness the creation of decorative porcelain. The skilled artists at Noritake are some of the best in the country. Every single handcrafted piece they produce makes for stunningly beautiful pieces that stand out in their exquisiteness and quality.

Visitors have the unique opportunity to learn about the process of crafting these fine pieces of artwork as well as the chance to try their hand and making their own pieces that you can truly treasur .

https://www.facebook.com/watch/?ref=external&v=895591864135148